We got an exciting call during the week from the guys at Method Build. Our house had arrived and it was sitting in a warehouse out in East Tamaki. Well our prefabricated Formance SIP panels that make up our house.

We eagerly headed out to see our house in the warehouse. Man it was cool to see and really throws the traditional model of building out the window. Just can’t wait to see them arrive on site and go up uber quickly!

You can read more about our prefabrication construction method over on this earlier post.

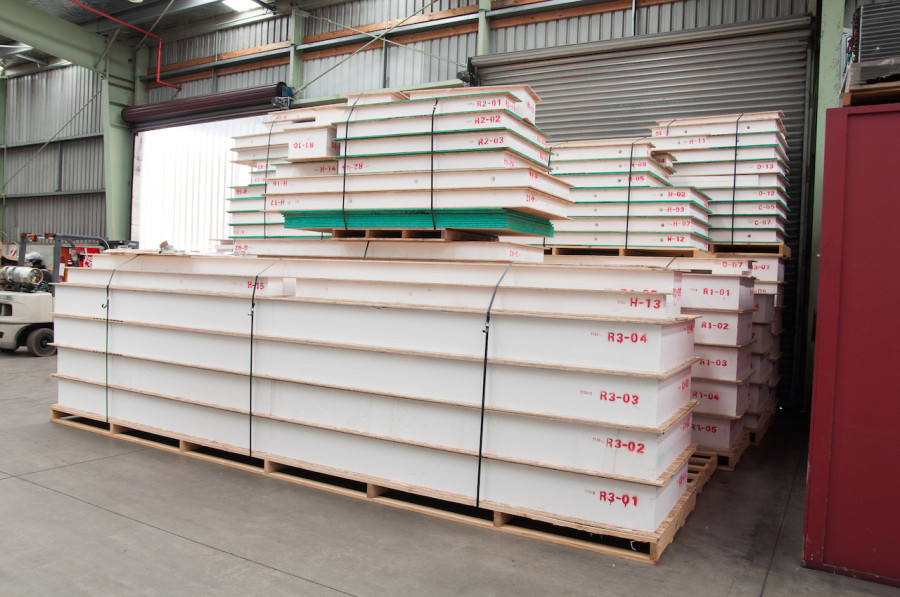

Our Formance SIP panels stacked to the roof. The long panels in the foreground will make up the ceiling in our living area and at 315mm thick, they will create an extremely efficient home.

Kylie in front of some of our wall panels. Such a different way to build but it really makes so much sense. Faster, stronger and warmer!

Each panel has a code on it, representing it’s place in our house. You can also make out the pre-cut chase holes in the wall panels for our wiring to run through.

Hi Ben and Kylie

Your project looks exciting, We are also building a SIPS home in Auckland. We were wondering if you are using the panels for your roof and if so, do you have any solutions to minimise the “popping” of the panels documented in some building blogs?

Are you using a balanced heating system, and how are you going to cool the house?

Many thanks

Hi Kim

Thanks for getting in touch. Awesome. Who are you using for your SIPs supplier/manufacturer? Yes, we have a 315mm SIPs ceiling, with 6m spans. But the exterior roof is not applied straight onto the SIPs. We have a cavity and structure to create the fall of our roof, then ply over that, then our Nuralite membrane roof is applied to that. It is also extensively vented too, to help with the heat differential, build up etc. From what I have read, this should eliminate the roof popping where most instances seem to be where the roof (iron/shingles etc) is applied directly over the SIPs panels and as the different materials heat/cool and expand/contract at different rates, the noise occurs.

Kylie’s Dad owns Climate Control and is looking at a custom ducted ventilation system for both heating and cooling. Although given the r values for the SIPs, it’s not going to need to be very big at all!

Hope that helps!

Hi guys,

I have really enjoyed following your journey, have learnt a lot and am particularly excited, as I’m sure you are, to see the final built product. Thanks for sharing your experience!

You and Kylie are a very sweet couple. I wish you all the best for 2015 and the future in your new home.

Enjoy!

Hey Hamish, thank you! Glad you’ve enjoyed following our build so far. You’re certainly right, we can’t wait to finally move into the house in a couple of months time!

All the best for 2015 to you too!

Hi,

We’re looking at SIP and wondered how you got on?

Seems to be nothing since January 2015…what happened? Is it done? What was the timeline for build and did it go smoothly? Looking at it for a small single level investment property. Cheers

Hi Gordon – have you looked through the rest of our site? We moved in about 15 months ago and absolutely love it. SIPS are brilliant – so thermally and structurally efficient. We wouldn’t change a thing. You can see some recent photos here: http://www.ourdreamhome.co.nz/uncategorized/8-months-in/ and here http://www.ourdreamhome.co.nz/our-build-diary/

Cheers

Ben