We Have A House

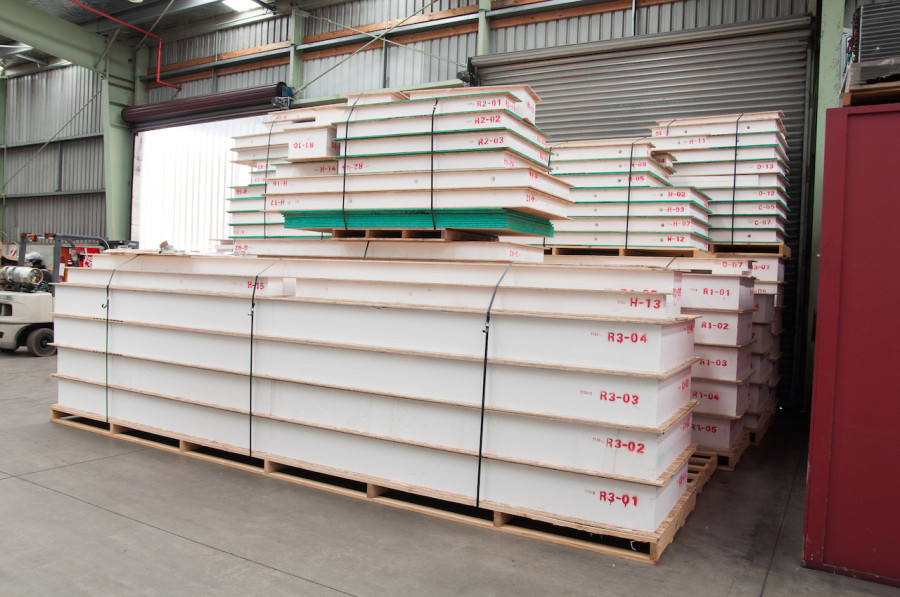

Well almost! Such an awesome couple of days as our bedroom pod appeared from nothing, to be an almost complete shell. Thanks to the prefabricated Formance SIP panels we are building with and our awesome builders. This method of building really is awesome and we can already see the benefits of using it, both the short term efficiency as well as the long term thermal efficiency and structural strength.

We couldn’t have been more excited or happier to see it all take shape, even better than we had imagined. And I loved spending a few days on site, lending a hand where I could, while not getting in the way or slowing progress up! It’s a pretty cool experience to help build your own home that’s for sure.

And then it began. Dan easily slides one of the first panels into place, forming the end wall of our bathroom.

Such an efficient system. In under an hour we had a large section of wall up, forming the bathroom and laundry. You can see the beautiful slit windows offering glimpses into the bush.

Loved being able to help put together our home. Just wish I could spend the next 2 months on site full time!

Taking shape beautifully. It was so awesome to see the pod materialise the way we had envisaged. Tucked perfectly under the bush canopy like it had always been there.

With the ceiling panels going in and sealing the building up, it suddenly felt like we had a real home!